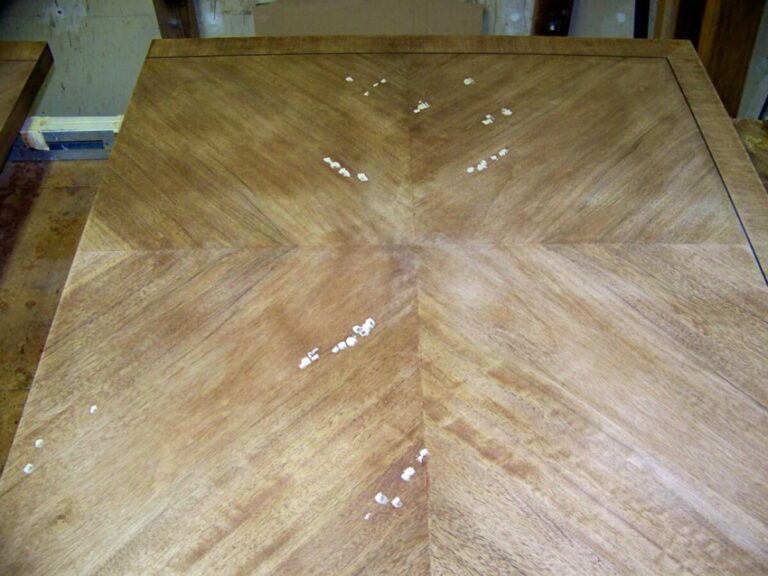

Mid-Century Modern Mastercraft Table Restoration

This project was completed June 15, 2015, the top of table was scratched and banged up, with parts of the veneer missing. The table had to be stripped back to bare wood, the missing veneer areas needed to be filled and touched up, then the wood was restored to the original high polish lacquer finish. The client wrote the following review on Angie’s List:

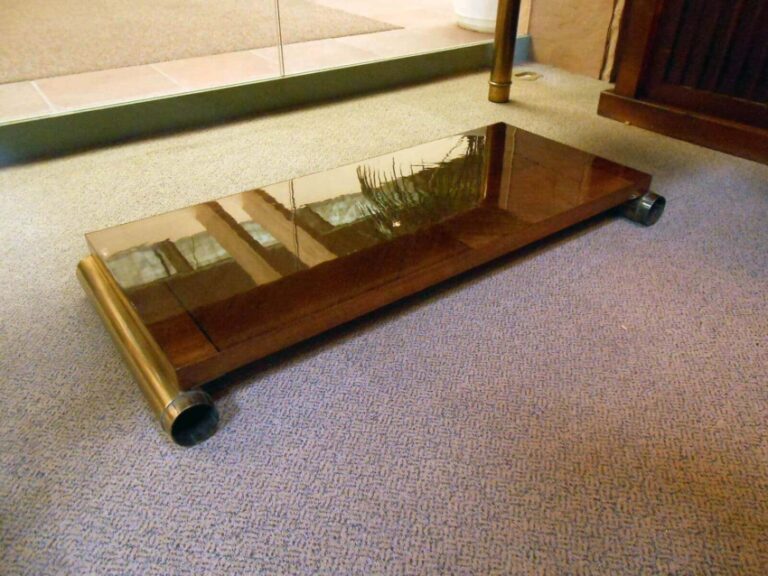

“I have a small business selling high quality mid-century furniture in Palm Springs, California. I had a couple of valuable Mastercraft pieces from the late 60’s that needed attention. One piece was a brass veneered triple vitrine. The hardwood subframe had a shrinkage issue due to climatic conditions here in the desert. This caused the brass veneer to lift in a few places. I interviewed some candidates for the job locally and nobody wanted to touch it. They all said to ship it to Los Angeles. The piece was heavy and fragile, so sending it to LA was not feasible. My research eventually brought me to Mark Fry at Museum Quality Restorations. I went to Mark’s shop in Desert Hot Springs and could tell immediately he knew how to fix the problem. He took the assignment. I had a second Mastercraft piece, a large dining table. It had a top of alternating blocks of book-matched veneer. Originally, it had a mirror-like finish that had been compromised in 40 years. Mark took this assignment as well.

Both of these assignments were handled beautifully and I was completely satisfied with the end result. I’m kind of a perfectionist, especially regarding my inventory. Mark fixed the veneer problem on the vitrine and made the dining table look new again. He charged me $500.00 for the vitrine and $2,500.00 for the top on the dining table. It was money well spent.

Now, Mark does incredible work, but like any true craftsman, (which he surely is) it’s not going to be particularly cheap or fast to get the work done. So, if you’re looking for cheap and fast, don’t waste his time. If, on the other hand, you have a valuable piece (and that can be a dollar or sentimental value) and you want it done correctly, then Mark is your guy. He’s a true renaissance man in a time when they’re hard to find. To have a resource like him in my back yard makes my business and life much easier. A happy relationship with any craftsperson depends on communication and expectation. If everyone is on the same page you have a happy ending to the story.”

Thanks for writing us a great review Steve! Here are the project photos followed by a screenshot of the actual review.

Whether you need us to restore a heirloom or refresh your favorite furniture – we are here to help! Contact us now to preserve and restore your treasured items.

Don't Wait Get In Touch Today